- PRODUCTS商品櫥窗

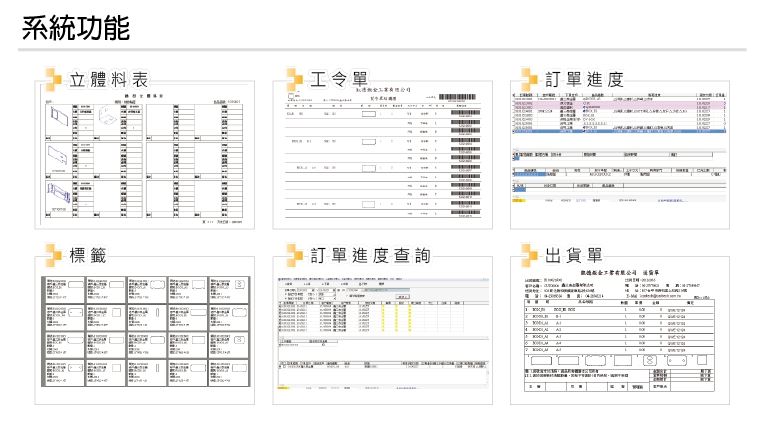

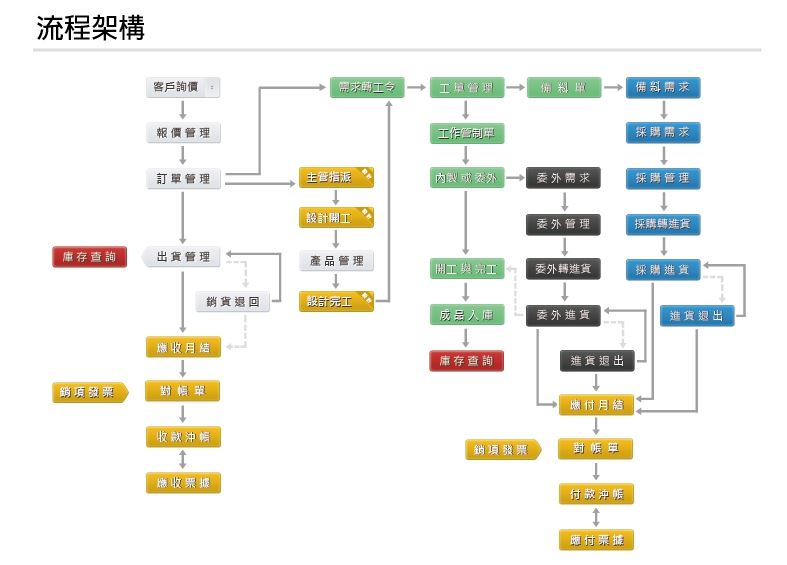

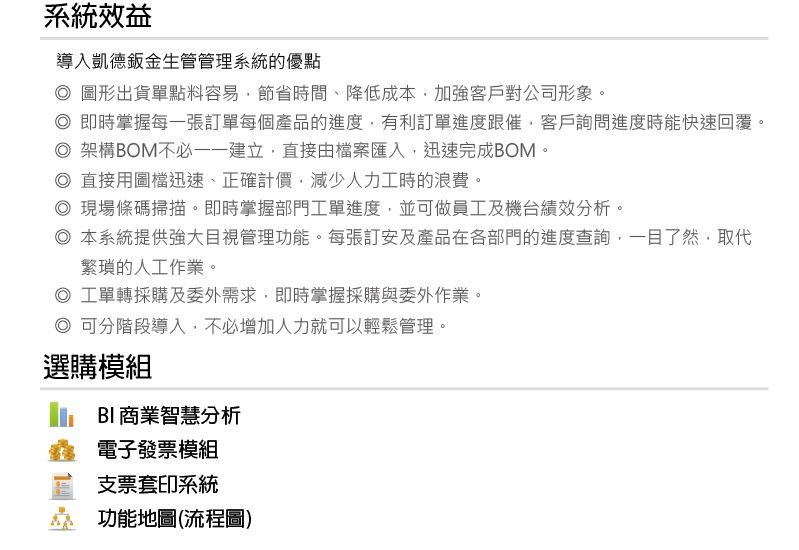

- ERP系統全方位解決方案(Sheet Metal Industry)

商品明細

火焰切割取圖計價(Flame Cutting Industry)

商品詳細介紹Product Introduction

火焰切割取圖計價(Flame Cutting Industry)

火焰切割一種金屬切割的常見加工方法,使用火焰進行切割。這種方法通常應用於較厚的金屬材料,例如碳鋼。以下是有關火焰切割的一些基本信息:

1.工作原理: 火焰切割是通過在金屬上應用燃燒的氧氣或其他氧化劑,產生高溫火焰並同時將金屬表面吹走,實現金屬的切割。這種方法主要用於碳鋼等容易燃燒的金屬。

2.適用材料: 火焰切割主要應用於厚度較大的金屬材料,特別是碳鋼。對於不銹鋼和鋁等非鐵金屬,通常會選擇其他切割方法,例如等離子切割或雷射切割。

3.設備: 火焰切割需要特殊的設備,包括氣體氧化劑、燃料氣體、切割嘴、切割機床等。氧氣和丙烷是常見的氧化劑和燃料。

4.適用場景: 由於火焰切割對於較厚金屬的適應性,它在船舶製造、建築、金屬加工等行業中得到廣泛應用。

Flame cutting is a common metal processing method that utilizes a flame for cutting. This technique is typically applied to thicker metal materials, such as carbon steel. Here is some fundamental information about flame cutting:

1.Principle of Operation: Flame cutting involves applying burning oxygen or other oxidizing agents to the metal, generating a high-temperature flame while simultaneously blowing away the metal surface. This process achieves the cutting of metals, particularly those prone to combustion, such as carbon steel.

2.Applicable Materials: Flame cutting is primarily applied to thicker metal materials, especially carbon steel. For non-ferrous metals like stainless steel and aluminum, other cutting methods such as plasma cutting or laser cutting are typically chosen.

3.Equipment: Flame cutting requires specific equipment, including oxidizing agents (such as oxygen), fuel gases (like propane or acetylene), cutting nozzles, and cutting machinery. Oxygen and propane are common oxidizing and fuel agents used in flame cutting.

4.Applications: Due to its adaptability to thicker metals, flame cutting finds widespread applications in industries such as shipbuilding, construction, and metal fabrication.

In summary, flame cutting is a widely used method for cutting thicker metal materials, especially carbon steel, in various industrial applications.