- PRODUCTS商品櫥窗

- ERP系統全方位解決方案(Sheet Metal Industry)

- 6. 實用版進銷存-金屬加工業(Inventory Management)

商品明細

實用版進銷存-金屬加工業(Inventory Management)

商品詳細介紹Product Introduction

實用版進銷存-金屬加工業(Inventory Management)

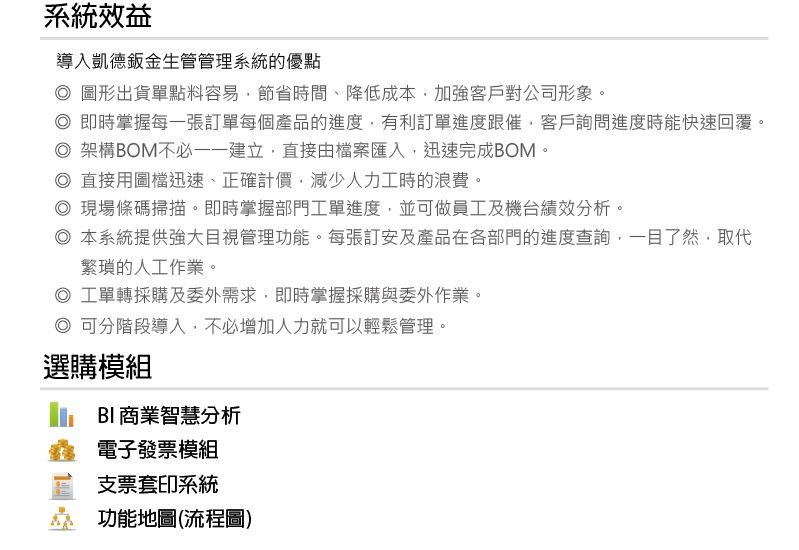

金屬加工業的進銷存管理是一個重要的業務流程,需要有效地追蹤原材料的進貨、產品的製造加工、以及最終成品的銷售。以下是一個實用的進銷存管理系統架構,特別針對金屬加工業的需求:

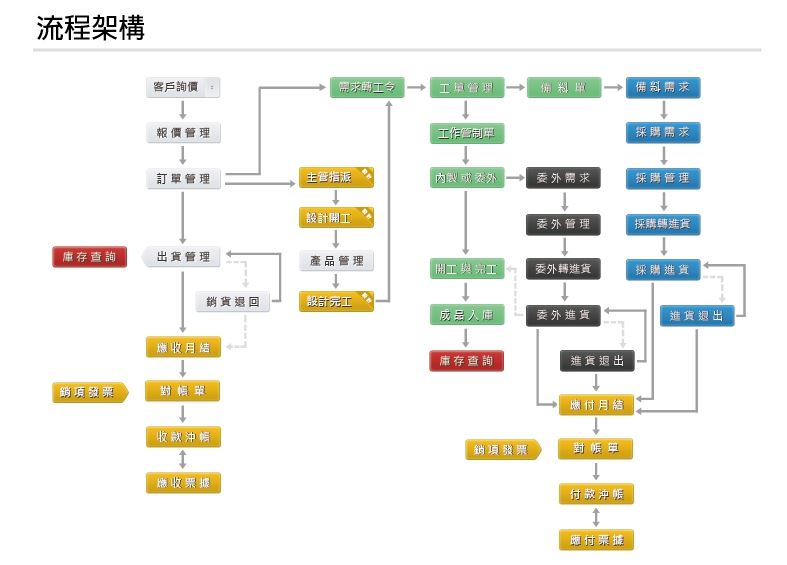

1.訂單管理:

記錄所有客戶訂單,包括訂單日期、數量、交付日期等。確保庫存充足,以滿足客戶需求。

2.客戶管理:

紀錄客戶資訊,包括聯絡方式、地址、訂單歷史等。提供客戶服務支援,包括查詢訂單狀態、解決問題等。

3.供應商管理:

紀錄各個供應商的基本資料,包括聯絡方式、地址等。追蹤每位供應商的交付表現,以確保及時的原材料供應。

4.原材料管理:

記錄所有進貨的原材料,包括金屬種類、數量、單位、價格等資訊。設定最低庫存量,以便及時補充原材料,避免生產中斷。

5.生產管理:

追蹤生產流程,從原材料到半成品再到最終成品。記錄每個生產階段的進度,以及使用的原材料和人工成本。

6.庫存管理:

監控庫存水平,包括原材料、半成品和最終成品。實行先進先出原則,確保庫存始終保持新鮮。

7.報表和分析:

生成進銷存報表,以監控業務績效。進行庫存分析,優化庫存水平,減少過多的庫存和庫存缺失。

8.財務整合:

整合進銷存系統與財務系統,以確保準確的財務報表。確保所有交易和成本都被正確地納入財務報告中。

這些功能將協助金屬加工業有效地管理進銷存,提高生產效率並確保客戶滿意度。

Inventory Management for Metal Processing Industry

Inventory management is a crucial business process for the metal processing industry, requiring effective tracking of raw material procurement, manufacturing processes, and the sale of final products. The following is a practical inventory management system framework tailored to the specific needs of the metal processing industry:

1.Order Management:

Record all customer orders, including order dates, quantities, delivery dates, etc. Ensure sufficient inventory to meet customer demands.

2.Customer Management:

Record customer information, including contact details, addresses, order history, etc. Provide customer service support, including order status inquiries and issue resolution.

3.Supplier Management:

Record basic information for each supplier, including contact details and addresses. Track the delivery performance of each supplier to ensure timely supply of raw materials.

4.Raw Material Management:

Record all incoming raw materials, including metal types, quantities, units, prices, etc. Set minimum inventory levels to facilitate timely replenishment of raw materials, avoiding production interruptions.

5.Production Management:

Track the production process from raw materials to semi-finished products and finally to finished products. Record the progress of each production stage, including the use of raw materials and labor costs.

6.Inventory Management:

Monitor inventory levels, including raw materials, semi-finished products, and finished products. Implement the first-in-first-out (FIFO) principle to ensure inventory freshness.

7.Reports and Analysis:

Generate inventory reports to monitor business performance. Conduct inventory analysis to optimize inventory levels and reduce excess or missing inventory.

8.Financial Integration:

Integrate the inventory management system with the financial system to ensure accurate financial reports. Ensure that all transactions and costs are accurately reflected in financial reports.

These functionalities will assist the metal processing industry in effectively managing inventory, improving production efficiency, and ensuring customer satisfaction.